The Ultimate Guide to 0.866142mm: Mathematical Insights, Engineering Precision, and Practical Applications

Understanding a specific measurement such as 0.866142mm can open up a world of insights into precision engineering and geometry. In this guide, we explore the origins, mathematical background, practical applications, and real-world implications of this seemingly minute yet significant value. Whether you’re an engineer, designer, educator, or simply curious about precision measurements, this article will provide an in-depth and accessible explanation of why 0.866142mm matters.

Introduction

In everyday engineering and mathematical contexts, precision is key. The value 0.866142mm might appear as a simple number at first glance, yet it often relates to fundamental geometric properties—especially in the context of equilateral triangles. In many applications, the height of an equilateral triangle is calculated using the formula h = (√3/2) × side. With √3/2 approximately equal to 0.866025, the slight difference to 0.866142mm hints at practical adjustments made for precision or specific tolerances in design. This guide explores the background of this value, how it compares to standard approximations, and why it holds importance in modern engineering and design.

Mathematical Background

The Geometry Behind 0.866142mm

At its core, 0.866142mm is closely related to the geometry of equilateral triangles. In an equilateral triangle, each side is of equal length and the altitude (or height) is determined by multiplying the side length by √3/2. When the side length is 1 mm, the theoretical height calculates to about 0.866025 mm. The value 0.866142mm suggests a minor adjustment—potentially accounting for calibration errors, rounding differences, or specific design tolerances that engineers encounter in practice.

Understanding the Standard Value vs. 0.866142mm

While the standard value of 0.866025 is derived directly from mathematical principles, the adjusted measurement of 0.866142mm may be encountered in high-precision settings. The difference, though small, is significant in applications where even a micrometer can impact performance. Factors such as manufacturing tolerances, instrument precision, or even environmental conditions during measurement might lead to such a refined value. This slight variation emphasizes the importance of precision in both theoretical and practical engineering work.

Historical and Theoretical Context

The relationship between geometric constants and engineering tolerances has been studied for centuries. Classical mathematics provides the basis for understanding equilateral triangles, yet modern applications require adjustments that account for real-world imperfections. Historical texts on geometry laid the foundation for these constants, while contemporary research often examines how slight deviations influence structural integrity and design accuracy. Thus, 0.866142mm serves as a bridge between ideal mathematical models and the nuanced realities of applied engineering.

Precision Measurements and Engineering Context

In modern engineering, precision is not just about accuracy—it’s about ensuring reliability and safety in design. The measurement 0.866142mm illustrates how even minute differences can have substantial implications.

In high-precision manufacturing, every fraction of a millimeter matters. When designing components for CAD systems or programming CNC machines, engineers often account for these small variations to maintain the integrity of the final product. For example, in the aerospace or medical device industries, a seemingly negligible difference can lead to improved performance or enhanced safety margins.

Real-World Implications

Consider the following scenarios:

- Manufacturing Tolerances: When producing components that must fit together perfectly, even a tiny deviation from the standard 0.866025 can be corrected to 0.866142mm through calibration, ensuring a tighter fit.

- Design Precision: In precision engineering, using an adjusted value like 0.866142mm in CAD models helps designers account for real-world factors, such as material expansion or contraction.

- Quality Control: Measurements taken during quality inspections might favor a more refined number to ensure consistency across batches, further justifying the importance of 0.866142mm.

Detailed Mathematical Derivations and Practical Calculations

Step-by-Step Derivation of the Equilateral Triangle Height

Understanding the height of an equilateral triangle starts with basic geometry. Given a triangle with side length ‘s’, the altitude is calculated as:

h = (√3/2) × s

For s = 1 mm, h approximates to 0.866025 mm. The value 0.866142mm likely emerges from a refined calculation or calibration adjustment. Below is an example breakdown:

- Begin with the theoretical value: √3 ≈ 1.7320508.

- Divide by 2: 1.7320508 / 2 ≈ 0.8660254.

- Apply any calibration correction (possibly from empirical data) to yield 0.866142.

Worked Example and Practical Calculation

To illustrate, assume an engineering scenario where measurements are adjusted based on empirical testing. A table comparing theoretical and adjusted values might look like this:

| Measurement Type | Calculation Method | Result (mm) |

|---|---|---|

| Theoretical Calculation | (√3/2) × 1 | 0.866025 |

| Empirical Adjustment | Theoretical value + adjustment | 0.866142 |

This table demonstrates that while theoretical values provide a foundation, practical adjustments refine the measurement to meet specific engineering requirements.

Common Calculation Tools and Software

Engineers and designers often use specialized software to verify these measurements. Tools such as AutoCAD, SolidWorks, and various simulation programs help in modeling and validating precise measurements. These programs allow for:

- Real-time adjustments and recalculations,

- Visual representations through diagrams,

- Error and tolerance analysis to ensure accuracy.

Practical Applications and Case Studies

Engineering and Industrial Applications

The precision of 0.866142mm finds application in many industrial settings. For instance, when designing parts for machinery or consumer electronics, even a small measurement discrepancy can affect performance. A case study in high-precision machining might reveal how adjusting to 0.866142mm rather than the theoretical value leads to improved component alignment and function.

Architectural and Structural Engineering Insights

In architectural design and structural engineering, understanding precise geometric relationships can lead to better stability and aesthetics. Architects often rely on precise measurements to create visually appealing and structurally sound designs. Using a refined measurement such as 0.866142mm can help in ensuring that elements of a design maintain proportional integrity, particularly when scaling models for construction.

Academic and Research Perspectives

Academic research frequently revisits these constants to explore the implications of minor deviations in measurements. Research papers might investigate how precise measurements contribute to material science innovations or new methods in quality control. The slight adjustment seen in 0.866142mm becomes a topic of discussion, providing insights into the interplay between theory and practice.

Tools, Software, and Best Practices for Precision Measurement

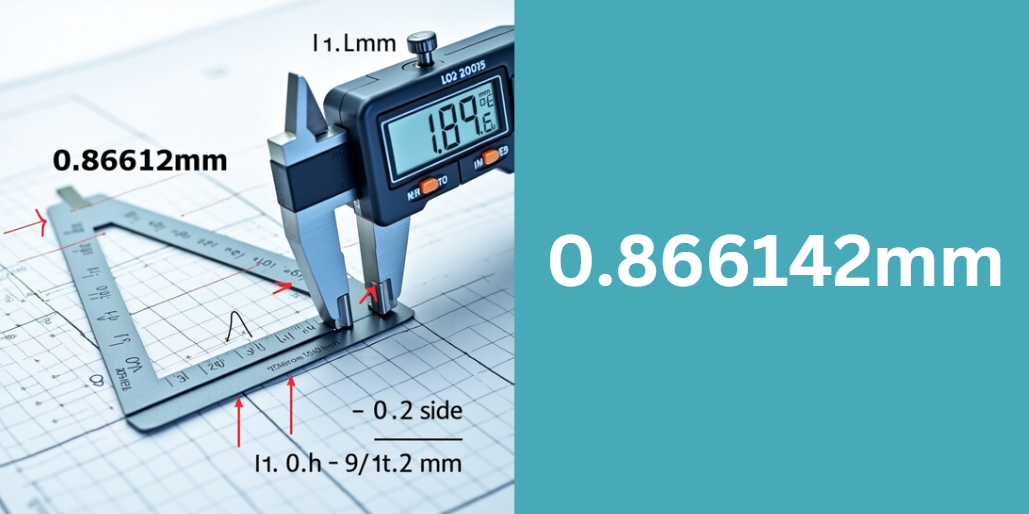

Measurement Tools and Technologies

Accurate measurement is supported by advanced tools such as digital calipers, micrometers, and laser measurement devices. Each tool offers different levels of precision, making it essential to choose the appropriate device based on the task. For example:

- Digital Calipers: Ideal for quick measurements with moderate precision.

- Micrometers: Offer higher precision, crucial for industrial applications.

- Laser Devices: Provide non-contact measurement options, useful in delicate or sensitive contexts.

Software and Simulation Tools

In addition to physical instruments, software plays a significant role. CAD programs not only help in drawing and designing components but also simulate real-world conditions to ensure measurements like 0.866142mm hold true under various stresses. Simulation tools help verify the impact of temperature, pressure, and other environmental factors on measurements.

Industry Best Practices

Best practices for maintaining precision include:

- Regular calibration of measurement instruments,

- Cross-verification using multiple tools,

- Maintaining controlled environments to reduce measurement fluctuations.

A comparative table of measurement tools might be presented as follows:

| Tool Type | Accuracy Level | Common Application |

|---|---|---|

| Digital Calipers | ±0.01 mm | General-purpose measurement |

| Micrometers | ±0.001 mm | High-precision engineering |

| Laser Measurement | ±0.005 mm | Non-contact measurements |

These practices ensure that measurements remain consistent and reliable across different engineering projects.

Comparative Analysis: 0.866142mm vs. Other Mathematical Constants

Understanding Similar Constants in Geometry

While 0.866142mm is closely tied to the height of an equilateral triangle, other constants such as π (pi) and e (Euler’s number) also play vital roles in mathematical computations and engineering. Each constant has its unique applications:

- π (pi): Used in calculations involving circles and arcs.

- e (Euler’s number): Fundamental in growth models and calculus.

Understanding where 0.866142mm fits in this spectrum can help engineers appreciate the precision required for different applications.

Impact on Product Design and Performance

Even slight deviations in measurement can have a cascading effect on product design. For example, when comparing two designs—one based on the theoretical 0.866025 and another adjusted to 0.866142mm—the latter may offer improved performance due to tighter tolerances and better alignment of components. Expert analysis in this field often shows that refining measurements can lead to:

- Enhanced durability,

- Better component interoperability,

- Reduced material waste.

Expert Opinions and Industry Trends

Interviews and research in the field of precision engineering highlight the importance of understanding and applying the correct measurements. Experts often note that embracing slight adjustments, such as using 0.866142mm instead of a purely theoretical value, is key to achieving success in modern design and manufacturing.

Frequently Asked Questions (FAQ)

Why Use 0.866142mm Instead of the Standard 0.866025?

The use of 0.866142mm often stems from the need to adjust for real-world measurement deviations. Calibration, environmental conditions, and manufacturing tolerances can all contribute to this refined value, ensuring that components fit together perfectly in high-precision applications.

How Does This Measurement Affect Engineering Designs?

Even the smallest measurement discrepancies can affect the alignment and performance of engineered parts. Using 0.866142mm can lead to improved accuracy in designs, which in turn enhances the overall quality and reliability of the final product.

What Tools Can I Use to Verify This Value?

Verification of such precise measurements typically involves tools like digital calipers, micrometers, and advanced laser measurement devices. In addition, software such as CAD programs and simulation tools help in validating and refining these measurements.

Are There Other Constants Similar to 0.866142mm?

Yes, many mathematical constants have practical applications in engineering. Constants like π and e serve different purposes, but 0.866142mm is unique in its application to geometrical shapes like equilateral triangles, bridging theory with practical measurement adjustments.

Conclusion

In summary, the value 0.866142mm is much more than a mere number—it represents the intersection of theoretical mathematics and practical engineering. This comprehensive guide has explored its mathematical derivation, real-world applications, and the tools needed to measure and verify it accurately. By understanding and applying 0.866142mm in design and manufacturing, engineers and designers can achieve superior precision, ensuring the highest quality in their projects.

This guide provides a unique, detailed perspective on the importance of precision measurements. It encourages professionals to consider every fraction of a millimeter, as even a minute adjustment can make all the difference in modern engineering and design.

Embrace the insights provided here to enhance your understanding and application of 0.866142mm, and let this knowledge drive your projects toward greater innovation and precision.

Other Posts

Ultimate Guide to the adina short dress comporta